Creating a DTF transfer-ready workspace is crucial for mastering Direct-To-Film (DTF) transfers. This involves organizing materials, placing custom DTF gang sheets, and ensuring quick access to tools like applicators and DTF film. Using high-quality press machines with precise control, along with a DTF gang sheet builder, allows for the creation of intricate, vibrant designs. To streamline pressing, prepare digital files in high-resolution PDF, check for issues, and follow specific application instructions for consistent outcomes.

Pressing DTF (Direct to Fabric) transfers effectively requires a meticulous approach. This guide outlines best practices for achieving flawless results, from preparing your workspace and choosing the right equipment to mastering pressing techniques and proper post-press care. By adhering to these steps, you’ll ensure your DTF transfers are not just ready to press but also produce high-quality, long-lasting designs.

- Preparing Your Workspace for DTF Transfers

- – Choosing the right equipment and materials

- – Setting up your work area for efficiency

Preparing Your Workspace for DTF Transfers

Preparing your workspace is half the battle won when it comes to pressing DTF (Direct to Film) transfers effectively. The first step is ensuring your work area is DTF transfer-ready. This includes clearing a dedicated space, free from clutter and distractions, where you can lay out all your materials and equipment in an organized manner. A clean and tidy workspace improves precision and efficiency, allowing for seamless transitions between each transfer process.

Additionally, consider the layout of your area to facilitate smooth workflow. Positioning your custom DTF gang sheets nearby, along with any necessary press tools and materials, will enable quick access during the pressing process. By optimizing your workspace, you set yourself up for success, ensuring that every aspect of the transfer is executed with precision and accuracy, ultimately leading to superior results in your final prints.

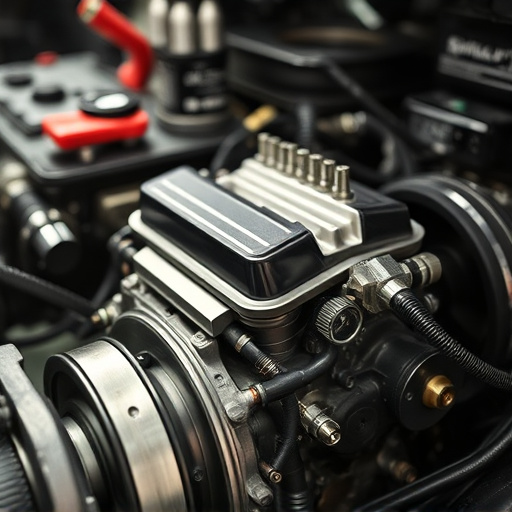

– Choosing the right equipment and materials

Selecting the appropriate equipment and materials is a cornerstone for achieving successful DTF (Direct-To-Fabric) transfers. When preparing for a DTF transfer, it’s essential to invest in high-quality press machines designed specifically for this technique. These presses should offer precise temperature control and even pressure distribution to ensure optimal results with various fabric types. Additionally, choosing the right ink and adhesive systems compatible with your chosen press is vital.

A DTF gang sheet builder can streamline the process by enabling efficient design preparation and printing. This tool allows for the creation of intricate, vibrant designs that are then precisely aligned on the fabric. With the right setup, you can produce DTF transfers ready to press, ensuring a seamless transition from design to final product.

– Setting up your work area for efficiency

To maximize efficiency when pressing DTF (Direct to Film) transfers, setting up your work area is a crucial first step. Organize your workspace with all necessary tools and materials within easy reach – this includes your DTF transfer film, a clean, flat surface for application, and precise tools like a spatula or applicator for even coating. Ensure good lighting conditions to facilitate accurate alignment and visibility during the entire process.

Proper file preparation is also key for successful DTF transfers. Convert all designs to the correct format (usually a high-resolution PDF) and check for any potential issues that could affect printing quality, like overlapping elements or poor contrast. Following detailed application instructions specific to your chosen DTF film will ensure consistent results.

Pressing DTF (Direct-to-Film) transfers effectively requires a well-prepared workspace and the right techniques. By choosing the appropriate equipment, setting up your work area efficiently, and following best practices, you can ensure that each DTF transfer is of the highest quality. Remember, making your workspace DTF transfer ready to press is the first step towards achieving consistent, professional results.